Eastern Treatment Plant Integration

Integrating a new plant into the ODS to replace a legacy Aspen system.

Project

$

0

K

Year complete

0

duration

0

mths

Integrating a new plant into the ODS to replace a legacy Aspen system.

SHARE

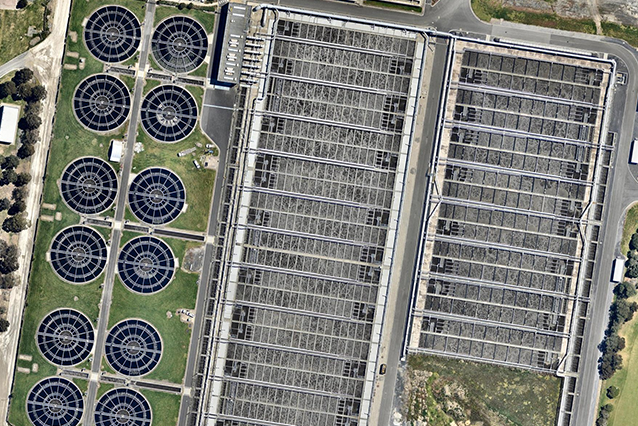

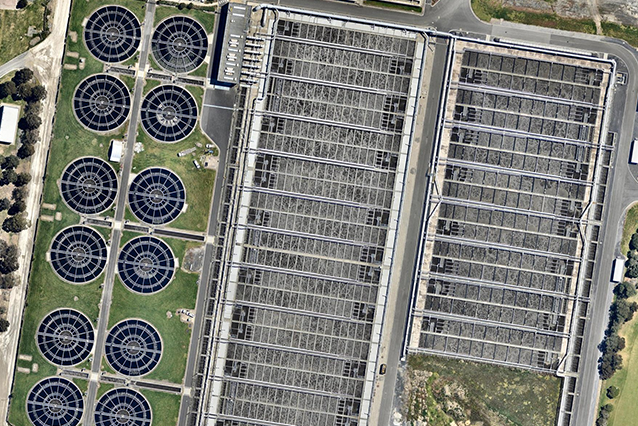

Melbourne Water has a number of different operational systems developed to suit different purposes including the Eastern Treatment Plant responsible for the transformation of sewage into class A recycled water through a three-stage treatment process which is provided to nearby customers as recycled water or released into the ocean at Boags Rocks under strict conditions set by EPA Victoria to protect the environment.

The objectives were:

In 2014 GTS had established an enterprise Operational Data Store (ODS) for Melbourne Water with the aim of integrating further data sources over time. The ETP integration project was the next major increment of data acquisition into the ODS.

The existing ODS comprised an Archive collective as well as PI Asset Framework and PI Vision servers.

Conceptually the project was straightforward, to set up interfaces to the PCS7, create an AF data model and migrate data from the legacy system, but there was substantial complexity under the surface:

GTS began with a plan, to identify the critical path tasks (such as long lead time firewall changes) and the subject matter experts (such as the Aspen and PCS7 administrator); to break up the key areas of focus into discrete streams, test assumptions, revise schedules and assign resources.

This resulted in four different workstreams:

Real-time Data

OSIsoft provided an off the shelf PI OPC HDA interface for the Siemens PCS7 with the OpenPCS server installed. The PI HDA interface provided built-in recovery/backfill after an outage and multiple interface instances were configured to optimise the throughput of data (Open PCS being a relatively poor performing server).

A redundant interface was originally specified but descoped by Melbourne Water since only one Open PCS source was provided.

Alarms & Events Data

A second off the shelf PI OPC A&E interface was installed specifically for the A&E data. Users wanted to view and analyse the data in ways not natively supported by PI System tools so another approach was required.

GTS designed a novel approach to fetch the data from the PCS7 into a small number of PI tags via the PI A&E interface, then implement a second PI RDBMS interface to fetch the data from the PI tags and load it into a SQL Server database.

This allowed the data to be stored and ‘forwarded’ by PI using off the shelf connectors while allowing users to leverage existing Microsoft BI tools to inspect the data.

Aspen Data Migration

There were approximately 18 years’ worth of data in the legacy Aspen system amounting to billions of events. As may be expected in legacy systems the data was not ‘clean’ and there were some challenges for example:

A reliable migration and validation process was needed to prove the data had all successfully migrated.

A data migration plan was drafted describing a process of configuring a Matrikon OPC server on the Aspen system, and an OSIsoft OPC interface to read the data into a TEST PI System.

Then extracting a sample dataset from Aspen to file and running a validation tool over the file comparing it with the Pi System to show that the interface migration had succeeded.

And then migrating the full data history in batches, with process to both monitor and report issues (such as described above) and validate the data as it migrated.

PI System Configuration

The PI Asset Framework is a powerful tool because it allows a logical, hierarchical structure to be defined that combines data from many sources with calculations or static data. This is a great way to abstract any complexity from the consumers of the data and to implement data structure standards.

There were approximately 20 asset types that had consistent, similar attributes accounting for about 70% of the total tags. A hierarchical data model was developed in AF for each of them so that the powerful features of AF templates and PI Vision could be leveraged.

Having established an AF structure, PI Vision Collections provided a powerful tool for operators to easily construct a ‘thumbnail’ view of critical asset information for each of the assets; and review that data in and filterable display.

PI System Training

One of the final project stages was the user training. GTS was very keen that users were empowered by the system to access and benefits form the data available through the ODS so a training plan was prepared in consultation with Melbourne Water change managers to identify:

The style of training GTS finds most effective references user guides but focusses on hands-on, workshop style of delivery allowing each participant to learn to use the tools while building something with their own data, that directly applies to their personal needs.

Training was delivered over a two-week period to all of the ETP users comprising:

Chief Executive Officer

Chief Executive Officer at GTS Group

Level 16 & 17, 1 Denison Street

North Sydney, NSW 2060

Australia

+61 1300 241 717

sales@gtsgroup.com.au

© 2024 GTS Group. All Rights Reserved.